blade clearance adjustment

QC11Y series hydraulic guillotine shearing machine

Key words:

QC11Y series hydraulic guillotine shearing machine

Classification:

Technical Specifications

1.The whole machine adopts the whole steel plate welding structure, the comprehensive treatment has good rigidity and stability.

2.The upper and lower blades are rectangular blades, with quick electric adjustment of blade clearance.

3.Shear stroke is controlled by time relay, and electric control adjusts shear Angle.

4.The rear stopper runs in the front and back direction,driven by the motor and displayed by the E21S system with fine tuning function.

Detail presentation

Technical Parameters of QC11Y/K Series CNC(Ordinary) Gate-Type Shearing Machine:

| Parameter Specification | Shearing Thickness mm | Shearing Width mm | Strokes min-1 | Backgauge Range mm | Shearing Angle (°) | Mainpower kw |

| QC11Y/K-6×2500 | 6 | 2500 | 16-35 | 20-580 | 30’-1°30 | 7.5 |

| QC11Y/K-6x3200 | 6 | 3200 | 14-35 | 20-580 | 30'-1°30 | 7.5 |

| QC11Y/K-6×4000 | 6 | 4000 | 10-30 | 20-580 | 30’-1°30 | 7.5 |

| QC11Y/K-6x5000 | 6 | 5000 | 10-30 | 20-800 | 30'-1°30 | 11 |

| QC11Y/K-6×6000 | 6 | 6000 | 8-25 | 20-800 | 30'-1°30 | 11 |

| QC11Y/K-8x2500 | 8 | 2500 | 14-30 | 20-600 | 30'-1°30 | 11 |

| QC11Y/K-8x3200 | 8 | 3200 | 12-30 | 20-600 | 30'-1°30 | 11 |

| QC11Y/K-8×4000 | 8 | 4000 | 10-25 | 20-600 | 30’-1°30 | 11 |

| QC11Y/K-8x5000 | 8 | 5000 | 10-25 | 20-800 | 30’-1°30 | 15 |

| QC11Y/K-8x6000 | 8 | 6000 | 8-20 | 20-800 | 30'-1°30 | 15 |

| QC11Y/K-12x2500 | 12 | 2500 | 12-25 | 20-800 | 30'-2° | 15 |

| QC11Y/K-12x3200 | 12 | 3200 | 9-25 | 20-800 | 30'-2° | 15 |

| QC11Y/K-12×4000 | 12 | 4000 | 6-20 | 20-800 | 30'-2° | 15 |

| QC11Y/K-12x5000 | 12 | 5000 | 6-20 | 20-800 | 30'-2° | 22 |

| QC11Y/K-12×6000 | 12 | 6000 | 6-20 | 20-800 | 30'-2° | 30 |

| QC11Y/K-12×7000 | 12 | 7000 | 6-20 | 20-800 | 30'-2° | 37 |

| QC11Y/K-12×8000 | 12 | 8000 | 6-20 | 20-800 | 30'-2° | 45 |

| QC11Y/K-12x10000 | 12 | 10000 | 4-18 | 20-800 | 30'-2° | 55 |

| QC11Y/K-12x12000 | 12 | 12000 | 4-18 | 20-800 | 30'-2° | 2*37 |

| QC11Y/K-16x2500 | 16 | 2500 | 9-20 | 20-800 | 30'-2°30 | 22 |

| QC11Y/K-16×3200 | 16 | 3200 | 8-20 | 20-800 | 30’-2°30 | 22 |

| QC11Y/K-16x4000 | 16 | 4000 | 8-15 | 20-800 | 30'-2°30 | 22 |

| QC11Y/K-16×5000 | 16 | 5000 | 7-15 | 20-800 | 30'-2°30 | 30 |

| QC11Y/K-16x6000 | 16 | 6000 | 6-15 | 20-800 | 30'-2°30 | 37 |

| QC11Y/K-16x8000 | 16 | 8000 | 5-15 | 20-800 | 30'-2°30 | 55 |

| QC11Y/K-16x10000 | 16 | 10000 | 4-15 | 20-800 | 30’-2°30 | 2*37 |

| QC11Y/K-16x12000 | 16 | 12000 | 3-12 | 20-800 | 30'-2°30 | 2*46 |

| QC11Y/K-20×2500 | 20 | 2500 | 7-20 | 20-800 | 30'-3° | 30 |

| QC11Y/K-20×3200 | 20 | 3200 | 6-20 | 20-800 | 30'-3° | 30 |

| QC11Y/K-20×4000 | 20 | 4000 | 5-15 | 20-800 | 30'-3° | 30 |

| QC11Y/K-20×5000 | 20 | 5000 | 4-15 | 20-800 | 30'-3° | 55 |

| QC11Y/K-20x6000 | 20 | 6000 | 4-15 | 20-800 | 30'-3° | 55 |

| QC11Y/K-20x8000 | 20 | 8000 | 4-15 | 20-800 | 1°-2.5° | 2*37 |

| QC11Y/K-20×10000 | 20 | 10000 | 4-14 | 20-800 | 1°-2.5° | 2*45 |

| QC11Y/K-20x12000 | 10 | 12000 | 3-12 | 20-800 | 1°-2.5° | 2*55 |

| QC11Y/K-25×2500 | 25 | 2500 | 6-15 | 20-800 | 1°-3.5° | 37 |

| QC11Y/K-25×3200 | 25 | 3200 | 5-15 | 20-800 | 1°-3.5° | 37 |

| QC11Y/K-25×4000 | 25 | 4000 | 4-15 | 20-800 | 1°-3.5° | 45 |

| QC11Y/K-25×5000 | 25 | 5000 | 4-12 | 20-800 | 1.5°-3.5° | 55 |

| QC11Y/K-25x6000 | 25 | 6000 | 3-12 | 20-800 | 1.5°-3.5° | 55 |

| QC11Y/K-25×8000 | 25 | 8000 | 3-12 | 20-800 | 1.5°-3.5° | 2*37 |

| QC11Y/K-32×2500 | 32 | 3200 | 4-12 | 20-800 | 1.5°-3.5° | 55 |

| QC11Y/K-32×3200 | 32 | 4000 | 4-12 | 20-800 | 1.5°-3.5° | 55 |

| QC11Y/K-32×4000 | 32 | 5000 | 3-12 | 20-800 | 1.5°-3.5° | 55 |

| QC11Y/K-32x6000 | 32 | 6000 | 3-12 | 20-800 | 1.5°-3.5° | 2*37 |

| QC11Y/K-40x2500 | 40 | 2500 | 4-10 | 20-800 | 2°-4° | 55 |

| QC11Y/K-40×3200 | 40 | 3200 | 4-10 | 20-800 | 2°-4° | 55 |

| QC11Y/K-40x4000 | 40 | 4000 | 3-10 | 20-800 | 2°-4° | 2*45 |

| QC11Y/K-50×2500 | 50 | 2500 | 3-10 | 20-800 | 2°-4° | 2*55 |

| QC11Y/K-50x3200 | 50 | 3200 | 3-10 | 20-800 | 2°-4° | 3*90 |

| QC11Y/K-60×3200 | 60 | 3200 | 2-8 | 20-800 | 2°-4° | 4*90 |

Description and specificationsgiven in thiscatalogue are subject tomodification without notice.

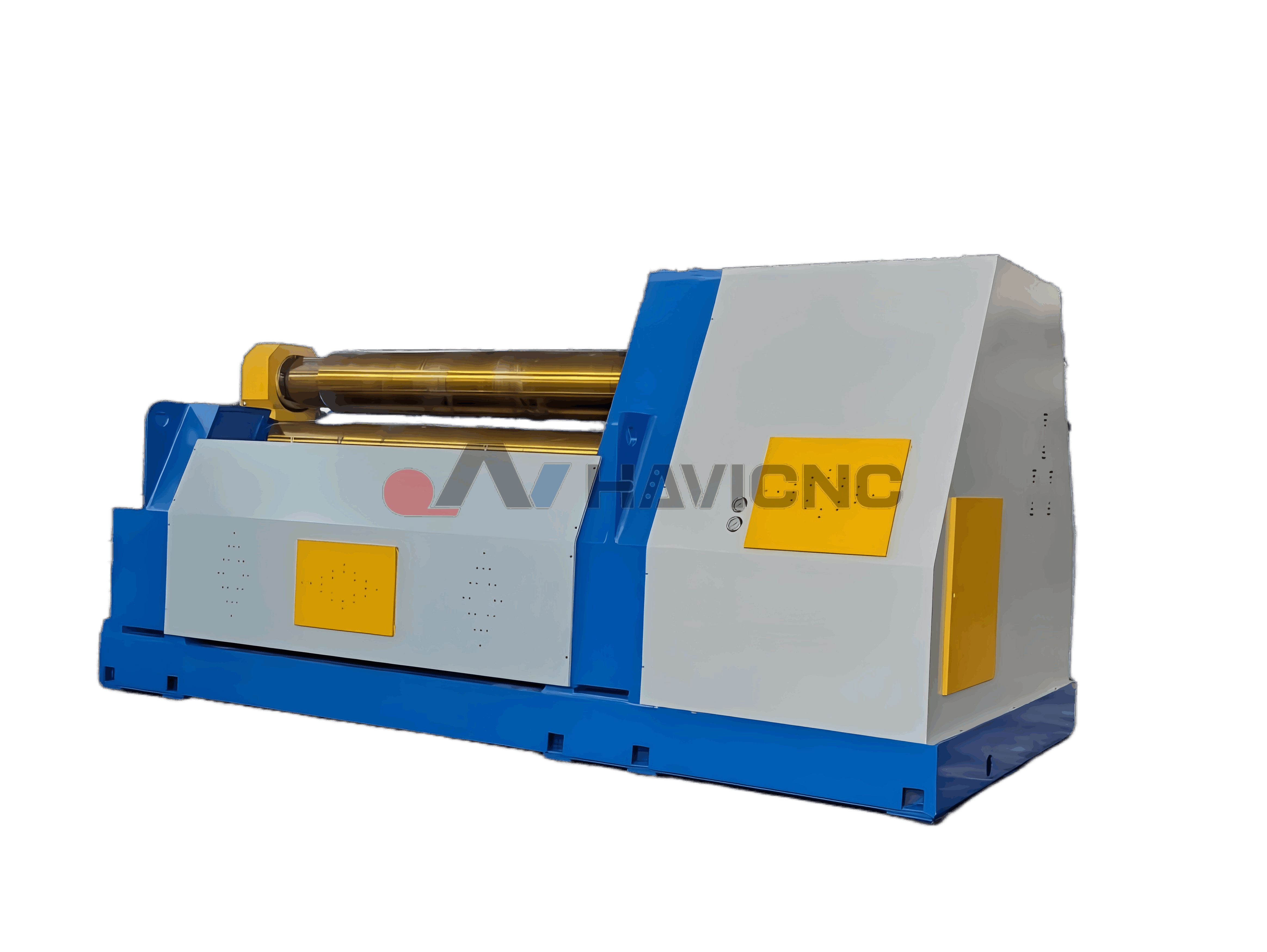

The hydraulic shearing machine is a powerful and precise metal cutting solution designed to handle a wide range of industrial applications. Engineered with robust construction and advanced hydraulic technology, this machine delivers clean, accurate cuts on various metal sheets with minimal deformation. The hydraulic shearing machine is ideal for use in fabrication workshops, automotive plants, and steel processing facilities.

Equipped with a high-performance hydraulic system, the machine ensures smooth and efficient operation. The adjustable blade clearance allows for accurate cutting of different material thicknesses, while the back gauge system improves cutting accuracy and repeatability. The hydraulic shearing machine also features a user-friendly control panel that simplifies setup and operation.

Safety is a top priority with the hydraulic shearing machine, incorporating protective devices and emergency stop functions to ensure operator well-being. Its durable frame and long-lasting components provide reliable performance, even in demanding environments. Whether you’re cutting mild steel, stainless steel, or aluminum sheets, this hydraulic shearing machine offers the power, efficiency, and precision required for high-volume production.

Related Products

Get a Free Quote

We will contact you within one working day. Please pay attention to your email.