HFH Automatic Submerged ArcWelding Production Line for Maximum diameter 500mm

Key words:

HFH Automatic Submerged ArcWelding Production Line for Maximum diameter 500mm

Classification:

Technical Specifications

Performance characteristics:

The HFH type automatic seam welding production line is a new product developed by our company in recent years. lt completes the seam welding of lamp poles in one operation.

Submerged arc welding is adopted, which is the first in the country. lt has a fast welding speed (2.5m/min),no pollution,no light emission,smooth surface,high direct weld penetration rate,simple operation,and a price lower than that of gas welding machines.This makes it the preferred product for lamp pole manufacturing enterprises.

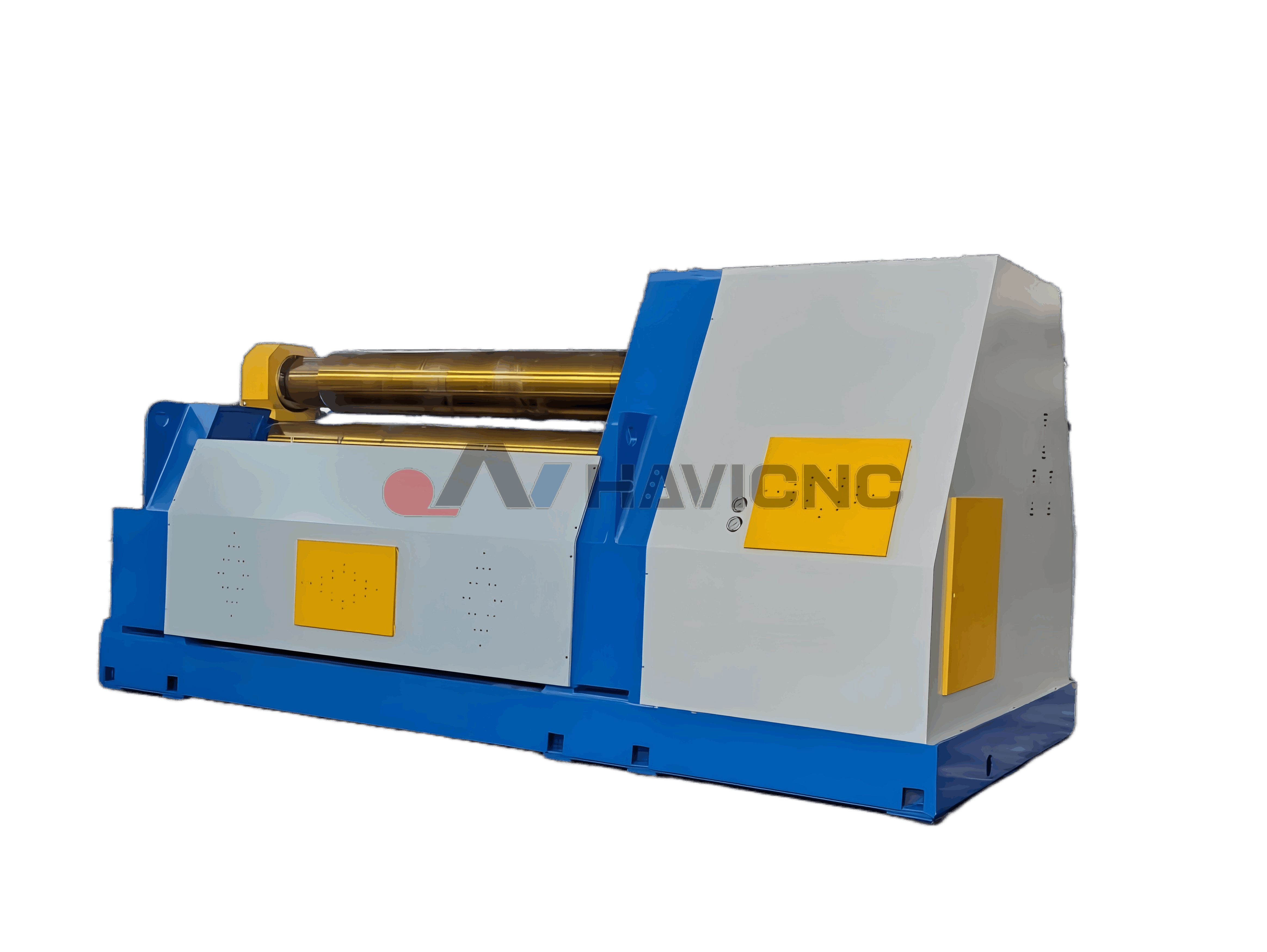

Partial Schematic Diagram of Lamp Pole Equipment:

The Automatic Submerged Arc Welding Machine is a state-of-the-art welding solution designed for high precision and efficiency in heavy-duty industrial applications. Equipped with advanced automation technology, this machine ensures consistent weld quality, reduced spatter, and minimal operator intervention. Ideal for welding thick materials, it is widely used in shipbuilding, pipeline construction, and pressure vessel manufacturing. The automatic submerged arc welding machine enhances productivity by delivering high-speed, deep-penetration welds with superior arc stability.

With user-friendly controls and customizable settings, this automatic submerged arc welding machine adapts to various welding requirements, including straight seams, circumferential seams, and longitudinal welds. Its robust design incorporates a flux recovery system, reducing waste and optimizing operational costs. The machine’s automatic wire feeding and voltage regulation ensure seamless performance even in demanding environments.

Safety and durability are key features of this automatic submerged arc welding machine. Built with high-quality components, it offers long service life and low maintenance needs. Whether for large-scale fabrication or precision welding tasks, this machine guarantees unmatched reliability. Upgrade your welding process with the industry-leading automatic submerged arc welding machine for superior results every time.

Related Products

Get a Free Quote

We will contact you within one working day. Please pay attention to your email.

NanTong HAVI CNC Machinery Co., Ltd.

Phone/WhatsApp: +86 17606524813

Address: Libao Development Area,HaiAn jiangsu China

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.