Shipbuilding

1. Precision machining: HAVI CNC equipment can achieve high-precision metal machining, including cutting, milling, drilling, etc., suitable for the manufacturing of ship structures and various ship components.

2. Machining of complex shapes: Ship parts usually have complex geometric shapes. HAVI CNC technology can achieve accurate machining of complex shapes through computer-controlled tool paths, improving production efficiency and product quality.

3. Automated production: HAVI CNC equipment can be integrated with automation systems to improve the automation level of production lines, reduce manual intervention, improve production efficiency, and reduce labor costs.

4. Material utilization rate: Through precise cutting and processing, HAVI CNC technology can minimize material waste and reduce production costs to the greatest extent possible.

5. Rapid prototyping: During the ship design phase, HAVI CNC technology can be used for rapid prototyping, helping designers validate design proposals and make necessary adjustments.

6. Customized production: Ship manufacturing often requires customization according to the specific needs of customers. HAVI CNC equipment can flexibly adjust processing parameters to meet the personalized needs of different customers.

7. Quality control: HAVI CNC systems are typically equipped with high-precision measuring and testing equipment that can monitor the machining process in real time to ensure product quality meets standards.

Through these applications, HAVI CNC has improved production efficiency, reduced costs, and enhanced product quality and consistency in the shipbuilding industry.

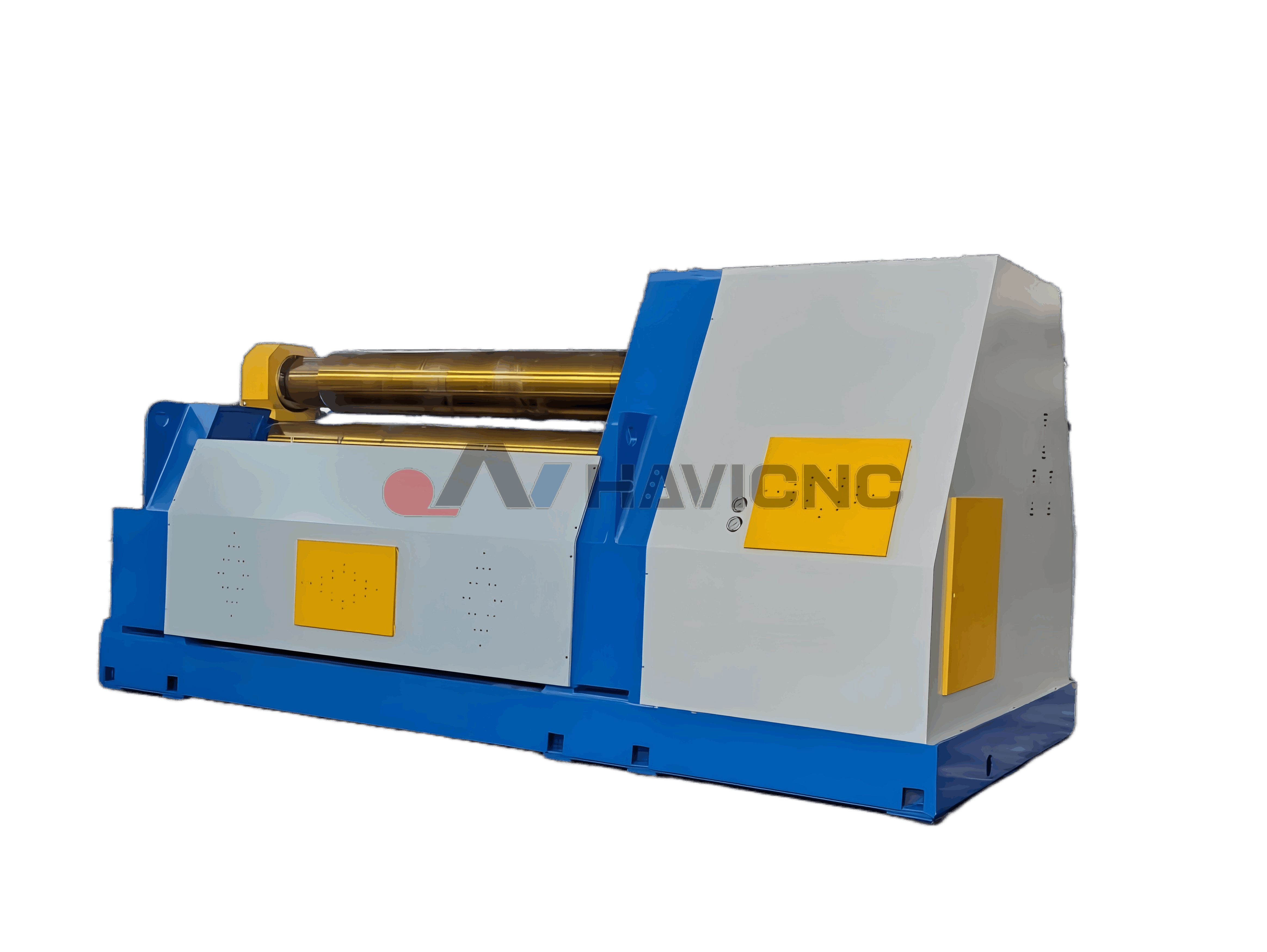

Related Products

NanTong HAVI CNC Machinery Co., Ltd.

Phone/WhatsApp: +86 17606524813

Address: Libao Development Area,HaiAn jiangsu China

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.