Machinery

Shearing machine

Function: By cutting metal sheets with upper and lower blades, precise size cutting can be achieved.

Application:

Aerospace: Used for cutting high-precision aluminum alloy sheets to meet the processing needs of aircraft components.

Household appliances: Processing metal parts such as refrigerators and air conditioning casings to improve production efficiency.

Kitchen equipment: Batch cutting of stainless steel kitchenware, such as stove countertops and cabinet frames.

Technical advantage: The QC11Y series hydraulic gate shearing machine adopts a deep throat design (such as QC11Y-25 * 6500), which can shear 6.5-meter-long plates and is suitable for processing large workpieces.

Bending machine

Function: Bend and shape metal sheets, and process complex curved surfaces.

Application:

Shipbuilding: Bending of ship steel plates to support complex ship design.

Automobile production: molding of body coverings and chassis components.

Steel structure building: bending processing of H-shaped steel and C-shaped steel, used for factory frame.

Technical advantage: WC67Y series hydraulic sheet metal bending machine, equipped with an electro-hydraulic servo system (such as WE67K-170T/4100), with a bending accuracy of ± 0.02mm, supporting automated production.

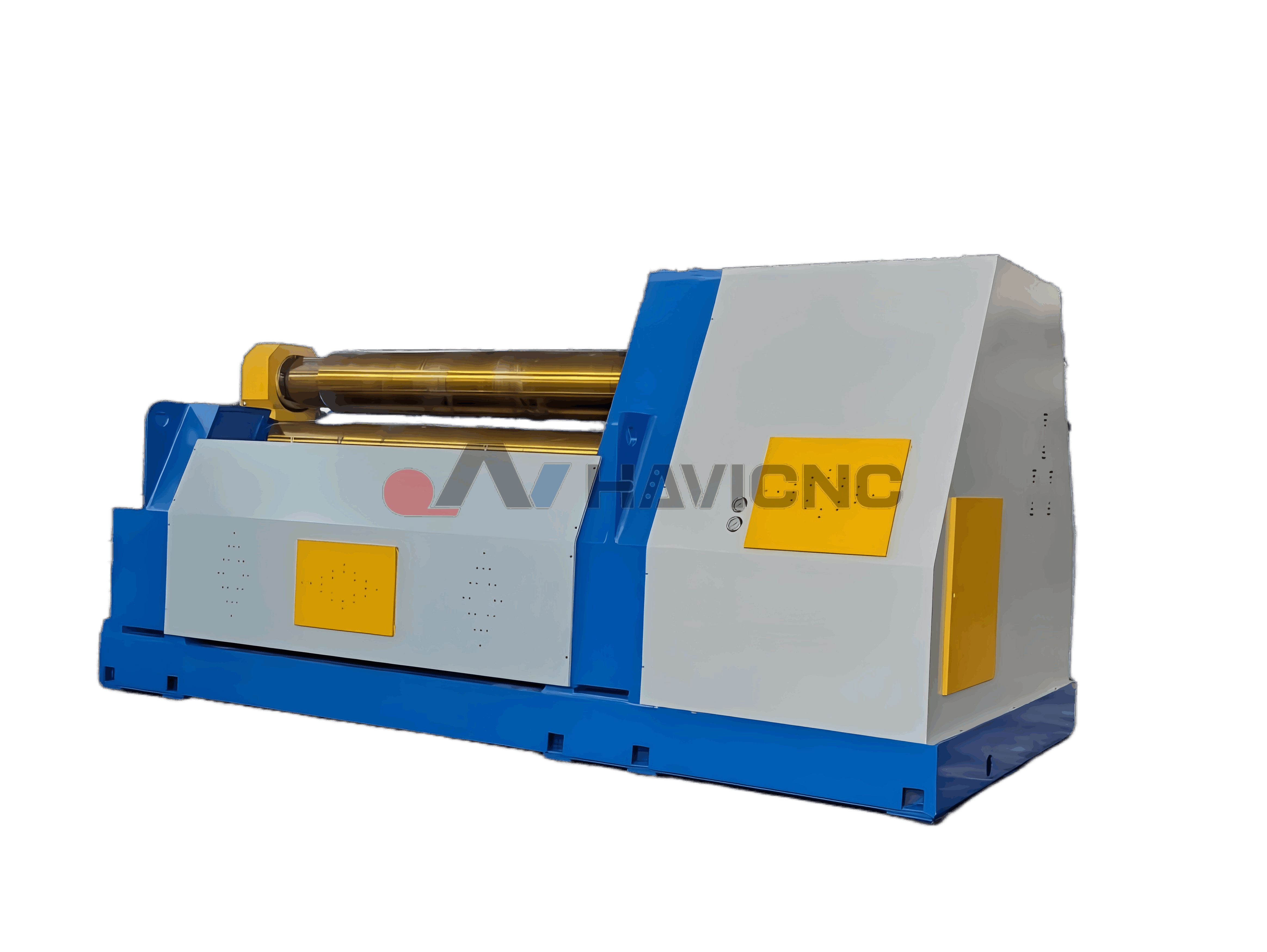

Rolling Machine

Function: Roll metal sheets into circles, arcs, or cones.

Application:

Petrochemical industry: Rolling of pressure vessel cylinders, such as oil storage tanks and reaction vessels.

Aerospace: Round processing of rocket fuel tanks, adapted to special alloy materials.

Technical advantage: W11Y series hydraulic three roll symmetrical plate rolling machine, supporting CNC operation, with a plate thickness range covering 3-200mm, meeting the requirements of multiple specifications.

Lamp pole equipment production line

Function: Integrate automatic welding, bending, straightening and other processes to achieve fully automated production of lamp posts and communication towers.

Application:

Smart city construction: efficient manufacturing of road light poles and monitoring poles.

In the field of communication: customized production of 5G base station towers.

Technical advantages: The dual machine linkage bending machine (such as WC67Y-1200/12000), combined with an automatic welding production line, can increase daily production by 40% and support non-standard customization.

Related Products

NanTong HAVI CNC Machinery Co., Ltd.

Phone/WhatsApp: +86 17606524813

Address: Libao Development Area,HaiAn jiangsu China

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.